Comprehensive Overview of Instrument Transformers Inc.

Catalog

| 1. | Company Profile |

| 2. | Product Ranges |

| 3. | Construction Types |

| 4. | Standard Burdens for VTs and CTs |

| 5. | Key Features and Benefits |

| 6. | Quality Assurance and Compliances |

| 7. | Innovations and Technologies |

Company Profile

Instrument Transformers Inc. (ITI) is a renowned manufacturer specializing in the production of precision-engineered current and voltage transformers. Established in 1973, ITI has been a leader in the instrument transformer industry for over four decades.

Instrument Transformers Inc. is headquartered in Clearwater, Florida, United States, and operates with a commitment to innovation, quality, and reliability. The company's extensive product portfolio includes a wide range of current transformers (CTs) and voltage transformers (VTs), designed to meet the diverse needs of modern power systems and electrical applications.

With state-of-the-art manufacturing facilities and a team of experienced engineers, Instrument Transformers Inc. ensures that its transformers adhere to the highest standards of quality and performance. The company employs rigorous testing and inspection processes to maintain consistency and reliability across its product line.

ITI's transformers find applications in various industries, including power generation, transmission, distribution, renewable energy, industrial automation, and more. Whether for metering, protection, or control purposes, ITI's transformers are trusted by utilities, manufacturers, and engineering firms worldwide for their precision, durability, and reliability.

Committed to customer satisfaction, Instrument Transformers Inc. provides exceptional service and support to its clients, offering technical expertise, customization options, and timely delivery. The company's dedication to excellence has earned it a reputation as a trusted provider of high-quality instrument transformers, serving as a vital component in the electrical infrastructure worldwide.

Product Ranges

Instrument Transformers Inc. (ITI) offers a comprehensive range of precision-engineered current and voltage transformers designed to meet the diverse needs of the electrical industry. Here's an introduction to some of ITI's product descriptions:

1. Current Transformers (CTs): ITI's current transformers are meticulously designed to accurately measure power systems' alternating current (AC). Available in various configurations and sizes, these CTs offer high accuracy, excellent linearity, and wide dynamic range, making them suitable for metering, protection, and control applications in utility, industrial, and commercial settings.

Example Model Numbers: ITI 145C3A, ITI 333C7, ITI 444C1

2. Voltage Transformers (VTs): ITI's voltage transformers, also known as potential transformers (PTs), are engineered to step down high voltage to a low voltage suitable for measurement and protection purposes. With exceptional voltage regulation, low distortion, and high insulation resistance, these VTs ensure reliable and accurate voltage measurements in power systems, substations, and industrial facilities.

Example Model Numbers: ITI 122P1, ITI 255P3, ITI 333P4

3. Multi-Ratio Transformers: ITI's multi-ratio transformers provide versatility and flexibility in voltage and current measurement applications. These transformers allow for multiple turn ratio configurations, enabling users to adapt to different voltage or current levels without the need for additional equipment. With compact designs and high accuracy, ITI's multi-ratio transformers offer efficient and cost-effective solutions for diverse measurement requirements.

4. Outdoor Transformers: ITI's outdoor transformers are ruggedized and sealed to withstand harsh environmental conditions, making them ideal for outdoor installations in substations, power distribution networks, and renewable energy facilities. These transformers feature robust construction, corrosion-resistant materials, and weatherproof enclosures, ensuring long-term reliability and performance in demanding outdoor environments.

Example Model Numbers: ITI 366OT1, ITI 488OT2, ITI 610OT3

5. Indoor Transformers: Designed for indoor installations where space is limited, ITI's indoor transformers offer compact and lightweight designs without compromising performance. These transformers are engineered to meet stringent safety and reliability standards for indoor electrical applications, including switch gear, control panels, and power distribution systems.

Example Model Numbers: ITI 277IN1, ITI 399IN2, ITI 511IN3

6. Specialty Transformers: In addition to standard CTs and VTs, Instrument Transformers Inc. offers specialty transformers tailored for specific applications or industries. These specialty transformers may include high-frequency transformers, low-profile transformers, encapsulated transformers, and custom-designed transformers to meet unique customer requirements and specifications.

Example Model Numbers: ITI 123SPT1, ITI 456SPT2, ITI 789SPT3

Overall, ITI's product lineup reflects its commitment to innovation, quality, and reliability, providing customers with high-performance transformers that meet the evolving needs of the electrical industry.

Construction Types

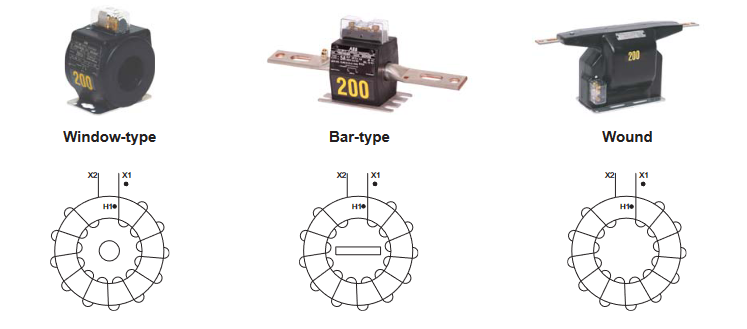

The principal forms of construction used for instrument transformers, together with standard symbols according to IEEE Standard C57.13, are shown below.

Types of Instrument Transformer Construction

Simple Basic Forms:

Construction Types:

Secondary Types:

Standard Burdens for Voltage Transformers (VTs) and Current Transformers (CTs)

Instrument Transformers Inc. (ITI) is a reputable manufacturer known for producing high-quality voltage and current transformers tailored to meet the stringent requirements of modern power systems. As part of its commitment to precision and reliability, Instrument Transformers Inc. offers a range of standard burdens for both voltage transformers (VTs) and current transformers (CTs).

1. Standard Burdens for Voltage Transformers (VTs):

• Instrument Transformers Inc. provides VTs with standard burdens to ensure accurate voltage measurements across various applications. These standard burdens are carefully selected to match the typical loads encountered in voltage measurement circuits, ensuring optimal performance and accuracy.

• ITI's standard burdens for VTs may include resistive loads, capacitive loads, and inductive loads, depending on the specific requirements of the application and the voltage levels being measured.

• By adhering to established standards and industry best practices, Instrument Transformers Inc. ensures that its VTs deliver precise voltage measurements while maintaining compatibility with a wide range of measurement devices and systems.

2. Standard Burdens for Current Transformers (CTs):

• Similarly, Instrument Transformers Inc. offers CTs with standard burdens designed to facilitate accurate current measurements in power systems. These standard burdens are carefully selected to match the typical loads encountered in current measurement circuits, ensuring reliable performance and accuracy.

• ITI's standard burdens for CTs may include resistive loads, burden resistors, and burden resistors with shunt capacitors, depending on the specific requirements of the application and the current levels being measured.

• By providing CTs with standard burdens, Instrument Transformers Inc. simplifies the integration of its transformers into measurement and protection systems, allowing for seamless operation and accurate data acquisition.

LOW VOLTAGE CURRENT TRANSFORMERS

Current Transformers

Applications

• For ammeters, wattmeters, and cross current compensation

applications

Features

• Wide range of window sizes

• Ratios 50:5A to 6000:5A

• 1 Amp secondaries are available

• Supplied with leads or terminals

• Integral feet or mounting brackets available

• UL Listed and CSA Approved

Current Transformers

Applications

• Designed for the operation of meters and instruments

• Utility metering small window

Features

• Designed for outdoor service

• Encapsulated in cast polyurethane resin

• Compression type terminals

• Ratios from 100:5A to 800:5A

• Dual ratio models available

• Engraved aluminum name plate

• Meet ANSI C12 size and mounting

LOW VOLTAGE POTENTIAL TRANSFORMERS

Voltage Transformers

Applications

• For three phase voltage measurement in AC power systems

Features

• Resin cast moulded plastic cases

• Integral fuses available on some models

• Designed to meet IEEE C57.13

• 50Hz design available

• UL Recognized and CSA Approved

Voltage Transformers

Applications

• For single phase voltage measurement in AC power systems

Features

• Resin cast moulded plastic cases

• Integral fuses available on some models

• Designed to meet IEEE C57.13

• 50Hz design available

• UL Recognized and CSA Approved

Key Features & Benefits

Instrument Transformers Inc. (ITI) offers a range of key features and benefits across its product line, ensuring reliable performance and accuracy in electrical measurement and protection applications. Some of the key features and benefits of ITI's transformers include:

1. High Accuracy: ITI's transformers are engineered for precision, providing accurate measurement of current and voltage levels in electrical systems.

2. Wide Dynamic Range: ITI's transformers offer a wide dynamic range, allowing them to accurately measure a broad range of current and voltage levels.

3. Robust Construction: ITI's transformers are built with robust materials and construction methods, ensuring durability and reliability in harsh operating environments.

4. Compact Design: ITI's transformers feature compact designs, making them suitable for installations where space is limited.

5. Standardized Burdens: ITI offers standardized burdens for its transformers, simplifying integration into measurement and protection systems and ensuring compatibility with industry standards.

6. Wide Application Range: ITI's transformers are suitable for a wide range of applications, including power generation, transmission, distribution, renewable energy, industrial automation, and more.

7. Compliance with Standards: ITI's transformers comply with industry standards and certifications, ensuring that they meet the requirements for accuracy, safety, and performance.

8. Customization Options: ITI offers customization options for its transformers, allowing customers to tailor the products to their specific application requirements.

9. Exceptional Customer Support: ITI provides exceptional customer support, offering technical expertise, customization assistance, and timely delivery to meet customer needs.

Quality Assurance & Compliances

Instrument Transformers Inc. (ITI) maintains rigorous quality assurance measures and ensures compliance with industry standards to deliver products of exceptional quality and reliability. Here are some key aspects of ITI's quality assurance and compliance practices:

1) Certifications and Standards: Instrument Transformers Inc. adheres to industry standards and certifications to ensure that its products meet stringent quality and performance requirements. This includes certifications such as ISO 9001 for quality management systems and UL listings for safety compliance.

2) Rigorous Testing: Instrument Transformers Inc. conducts thorough testing and inspection processes at various stages of production to verify the performance and reliability of its transformers. This includes tests for accuracy, insulation resistance, dielectric strength, temperature stability, and more.

3) Quality Control Procedures: Instrument Transformers Inc. implements comprehensive quality control procedures to monitor and maintain consistency in product quality. This involves strict adherence to manufacturing specifications, quality checkpoints, and defect detection measures throughout the production process.

4) Supplier Quality Management: Instrument Transformers Inc. works closely with its suppliers to ensure that raw materials and components meet the required quality standards. Suppliers are carefully vetted and monitored to maintain the integrity of ITI's supply chain.

5) Continuous Improvement: Instrument Transformers Inc. is committed to continuous improvement in its quality assurance processes and product offerings. Feedback from customers, industry experts, and internal stakeholders is carefully considered to identify areas for enhancement and refinement.

6) Compliance with Regulatory Requirements: Instrument Transformers Inc. ensures compliance with regulatory requirements and safety standards governing the design, manufacturing, and testing of electrical transformers. This includes adherence to regional regulations such as ANSI, IEEE, IEC, and CSA standards.

7) Documentation and Traceability: Instrument Transformers Inc. maintains detailed documentation and traceability records for its products, including material certifications, test reports, and inspection records. This enables traceability of products throughout the manufacturing process and facilitates quality audits and compliance assessments.

By prioritizing quality assurance and compliance, Instrument Transformers Inc. demonstrates its commitment to delivering products of the highest quality and reliability to its customers. These practices ensure that ITI's transformers meet or exceed industry standards and performance expectations, providing customers with confidence in their electrical systems.

Innovations & Technologies

Instrument Transformers Inc. (ITI) places a strong emphasis on innovation and technology advancements in transformer design and manufacturing. Here are some key aspects of ITI's innovation and technology initiatives:

1. Research and Development (R&D): Instrument Transformers Inc. invests in research and development activities to explore new technologies, materials, and manufacturing processes that can enhance the performance and reliability of its transformers. This includes collaboration with industry partners, academic institutions, and research organizations to stay at the forefront of transformer technology.

2. Advanced Design Techniques: ITI utilizes advanced design techniques, such as computer-aided design (CAD) software and simulation tools, to optimize transformer designs for performance, efficiency, and reliability. This allows ITI to develop transformers with improved accuracy, reduced losses, and enhanced durability.

3. Material Science: Instrument Transformers Inc. continuously evaluates new materials and insulation technologies to improve the thermal and electrical performance of its transformers. By leveraging advancements in material science, ITI develops transformers that can operate efficiently under a wide range of operating conditions and environmental challenges.

4. Integration of Smart Technologies: ITI explores the integration of smart technologies, such as sensors, communication interfaces, and diagnostic capabilities, into its transformers. These smart features enable remote monitoring, condition-based maintenance, and predictive analytics, enhancing the reliability and efficiency of electrical systems.

5. Environmental Sustainability: Instrument Transformers Inc. is committed to environmental sustainability and explores eco-friendly manufacturing processes, recyclable materials, and energy-efficient designs for its transformers. By reducing environmental impact throughout the product lifecycle, ITI strives to contribute to a greener and more sustainable future.

6. Industry Collaboration: ITI collaborates with industry partners, standards organizations, and regulatory bodies to stay informed about emerging trends, regulations, and best practices in transformer technology. This collaboration fosters knowledge sharing and facilitates the adoption of innovative solutions in transformer design and manufacturing.

Consultation