Ultimate Guide to Electronic Components & Circuit Design (2025 Update)

Components AnalysisExplore our 3 main knowledge domains:

- Component Selection Criteria (QFN vs. BGA packaging)

- PCB Layout Best Practices (EMI/EMC mitigation)

- Supply Chain Intelligence (2024 lead time forecasts)

Latest Industry Report

Download Q1 2025 Electronic Components Market

Outlook (PDF) →

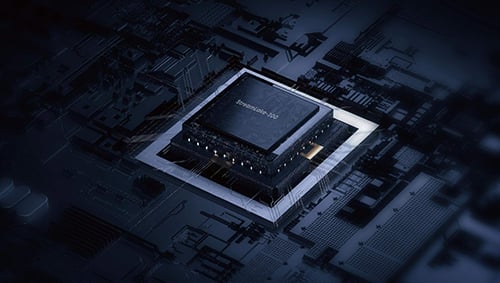

How ADAS sensor innovation protects road safety and reduces traffic accidents

Traffic safety is a huge challenge - more than 1.1 million people are killed each year in road traffic accidents, and an estimated 20 to 50 million more are injured.In this article, we will explore the role of ADAS in improving road safety and the various sensor technologies that are critical to achieving this goal.

knowledge Hub